|

Edwards

55 ton

|

|||||

|

|||||

EDWARDS 55 TON Jaws IV IRONWORKER MACHINE:

With

everything is made in the USA, the Edwards 55 Ton Jaws IV Ironworker machine

is a super-versatile well engineered machine. This machine is designed

to do all the ironwork needed at your fabrication shop like a swiss army

knife. Our Edwards Ironworker includes a Punching Assembly, a Pedestal

Die Table, Flat Bar Shear, Angle Iron Shear and a universal open tooling

Jaw designed to accept optional Tooling Accessories such as the Press

Brake, Coper-Notcher, Pipe Notcher, V-Notcher, Rod Shear or even a 2nd

Punching Assembly! We also offer the machine with a Hydraulic Powerlink

Connector Panel included free to allow it to power the Edwards 10 Ton

Tube/Pipe Bender, Horizontal Press Brake, Roll Bender, 20 Ton, 40 ton,

60 ton or 110 ton hydraulic Shop Press. If you feel this Ironworker Machine

is not big enough please note that we also have the more powerful 65

ton and 120 ton models

with 24 inch wide flat bar shear and the 100

ton and 120 ton model have a huge 6 x 6 x 1/2" capacity angle

iron shear. All the Edwards

Ironworker machines 55 ton and larger come with at least 4 hydraulic

powered work stations, hydraulic powerlink, electric stroke control, OSHA

compliant safety guarding, and UL approved controls. And dont forget to

look at the huge list of metalworking options with photos shown below!

**********************************************************

FEATURES:

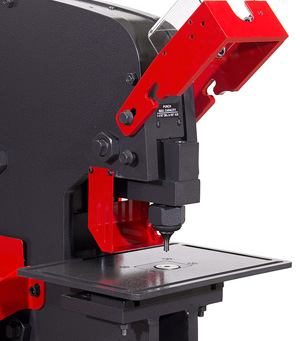

* Hole Punching Assembly installed on the left side

* Extra hydraulic jaw Tool station on the right side

* Flat bar shear built in - blades included - low rake

* Angle shear built in - blades included

* Electronic Up and Down Stroke Control System

* Adjustable steel punch strippers

* Fast adjusting hold down bars

* Threaded holes in tables for jigs

* Pedestal Die Table (for punching angle iron 2" on center)

* Threaded hole on back for optional back gauge

* Slots for gauge feeding tables

* Comfortable working heights

* Remote foot pedal operation

* Direct drive pump - no belts

* Fully Guarded

* Sound insulated

* Hydraulic system fully charged - ready to operate

* Made in USA

PUNCHING CAPABILITIES:

Punching Capacity: 55 Tons

Throat: 7.5"

Standard Punch: 1-1/16" diameter hole thru 5/8" plate

or a 7/8" diameter in 3/4" plate

Optional Oversize Punching Assembly: 1-9/16" diameter in 3/8" plate

FLAT BAR SHEARING:

Shearing Capacity: 55 Tons

Max.

width: 1/2" x 12" or 3/8" x 14"

Max. thickness: 3/4" x 4"

Max. round capacity: 7/8"

Max. square capacity: 7/8"

ANGLE SHEARING:

Maximum Size: 4" x 4" x 1/4" angle iron

Maximum thickness: 3" x 3" x 3/8" angle iron

All ratings are based on A36 steel @ 65,000psi max tensile strength

GENERAL SPECIFICATIONS:

Throat depth: 7-1/2"

Open height: 8-1/8" (important to fit custom die sets)

Shut height: 6-7/8"

Stroke: 1-1/4"

Cycle time: 2 seconds to shear 1/2" x 2" steel flat bar

Hydraulic pump size: 3.5 gpm - 1 stage @ 2500psi

Hydraulic Cylinder: 2.5" cylinder

Machine Dimensions: 36" x 44" x 56" High

Machine weight: 2480 Lbs.

ELECTRIC MOTOR CHOICES (*IMPORTANT*):

Standard: 5 HP, 3 phase, 230 volts, 3450 RPM, 14 amps

(or you can order 3 phase, 208 volts, 14 amps)

Electric motor options that cost extra:

5 HP, 3 phase, 440/480 volts (Extra cost)

5 HP, 3 phase, 575 volt, 7 amps (Extra cost)

5 HP, 1 phase, 208 volts, 26 amps (Extra cost)

5 HP, 1 phase, 230 volts, 26 amps (Extra cost)

ADVERTISED

PRICES:

We are not permitted to show you our lowest price so call us or click

to request a quote to get a better deal that includes discounted shipping

and a FREE Tool Box of 8 Punch & Die Sets!

The machine is available in the following electrical configurations!

Edwards 55 ton @ 1 phase, 230 volts

Edwards 55 ton @ 3 phase, 230 volts

Edwards 55 ton @ 3 phase, 208 volts

Edwards 55 ton @ 3 phase, 460 volts

Edwards 55 ton @ 3 phase, 380 volts

Edwards 55 ton @ 3 phase, 575 volts

Click

to Request Our Lowest Discount Price and info packet

*************************************

with Hydraulic Powerlink Connection Panel:

with Hydraulic Powerlink Connection Panel:

Edwards 55 ton with Hydraulic Powerlink @ 1 phase, 230 volts

Edwards 55 ton with Hydraulic Powerlink @ 3 phase, 230 volts

Edwards 55 ton with Hydraulic Powerlink @ 3 phase, 208 volts

Edwards 55 ton with Hydraulic Powerlink @ 3 phase, 460 volts

Edwards 55 ton with Hydraulic Powerlink @ 3 phase, 380 volts

Edwards 55 ton with Hydraulic Powerlink @ 3 phase, 575 volts

Click

to Request Our Lowest Discount Price and info packet

*************************************************

OPTIONS AVAILABLE for the Edwards 55 ton Ironworker:

-------------------------------------------------------------------------

|

TOOL BOX OF 8 round PUNCH & DIE SETS: FREE

with purchase of a new Ironworker! |

|||

Round Punch & Die |

Oblong Punch & Die |

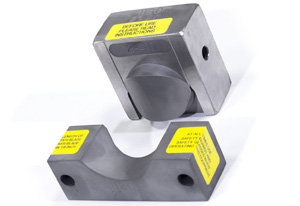

HARDENED PUNCH & DIE SETS

ROUND up to 1-1/16" The

die will have 1/32" clearance over the punch. |

||

Square Punch & Die |

Hex Punch & Die |

|||

|

COPER-NOTCHER: Coper

Notcher tool is used to bite off a piece of metal instead of using

a vertical bandsaw or torch. This tool has an upper jaw the bites

down into a lower jaw. The capacity to notch steel is 2-1/2" wide

up to 4" long in steel up to 5/16" thick. It is capable of biting

off a square shape, rectangle shape or V-shape. The rectangular

notch is useful for coping back a flange on a piece of angle iron

so it can fit up against another angle or channel at 90 degrees.

You can V-shape notch by turning your part at 45 degrees to the

machine. V-notching is useful when making a frame out of angle iron.

You V notch where you plan to bend the angle to 90 degrees. It easily

mounts in the open jaw on the right side of the machine. Click to

see a VIDEO.

|

|||

|

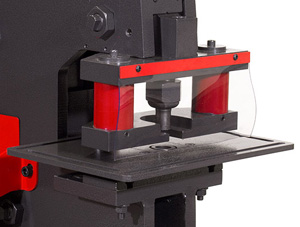

PRESS

BRAKE TOOL: Bend

flat steel that is up to 1/4 inch thick! Sometimes 3/8" thick.

This Press Brake Tool includes a standard wedge shaped top die and

a V-shaped four-way bottom die that allows for 1/16", 1/8", 3/16",

and 1/4" material to be bent to a 90° angle or smaller angle. The

bottom brake die is held with brackets that easily bolt to the mounting

table. Repeat the same bend angles by using the Ironworker electric

stroke control to stop the top die at the desired depth for the

angle you bend. |

|||

|

PRESS BRAKE TOOL BACK GAUGE: How to make REPEAT BENDS? Use this Back Gauge to measure the bend line distance for your press brake tool along with using the electric stroke control that is included with your Edwards 55 ton Ironworker. Just bolt it on to the Edwards Ironworker Brake Tool. It has an easy to use hand crank to position it with your tape measure. |

|||

|

PIPE

NOTCHING TOOL: The

Pipe Notcher saves the time of cutting and grinding to make a semi-circle

saddle style 90 degree joint connection of one piece of pipe to

another. Just stick the end of your pipe into the housing and step

on the foot pedal, then rotate 180 degres and repeat. Total time

to make a perfect notch is 8 seconds. Great for making railings

and cattle fencing out of schedule 40 pipe. Schedule 80 size and

Tubing size notchers are available on special order. To order you

buy the Pipe Notcher Housing plus the Notching Die. The safety guard was removed for the photo, but you must use the safety guards to help prevent accidents. |

|||

|

TURRET FOR PIPE NOTCHERS: This turret holds up to 3 different size pipe notching dies and rotates so that you can quickly position the size you want for your next notch. It easily mounts in the open jaw on the right side of the machine. |

|||

|

ANGLE V NOTCHER: The Angle Notcher bites out a 92° V-notch out of the lower leg of angle iron. V-notcher works on angle iron up to 3" x 3" x 1/4" size. This is great for making steel frames out of angle iron that is to be bent at 90 degrees. It easily mounts in the open jaw on the right side of the machine. |

|||

|

ROD SHEAR: The flat bar shear on the Ironworker can cut round rod but the ends do not look pretty. If you need to cut a lot of solid round rod without the blade leaving a distorted flat spot at the end, then you will want this tool. It cuts 1/4", 3/8", 1/2", 5/8", 3/4" and 1" solid round rod. It easily mounts in the open jaw on the right side of the machine. |

|||

|

BACK

GAUGE, Manual Cut (shown) The

Back Gauge measures out 48 inches for repeat cutting of parts to

length on the Angle Shear and Flat Bar Shear. On the back of the

55 ton Ironworker there is a threaded hole to screw in this Back

Gauge. |

|||

|

OVERSIZE PUNCHING ASSEMBLY If you need to punch holes larger than 1-1/16 diameter, then you need either the Oversize Punching Assembly (1-9/16" capacity) or the Extra Large 241 Punching Assembly (up to 4" capacity). The Extra Large 241 Punching Assembly can also hold special multi-hole punches so you can punch unusual shapes or multiple holes at one time as long as they can fit within a 4" circle. The safety guard was moved for the photo, but you must use the safety guards to help prevent accidents. |

|||

|

3/8"

thick PUNCH GAUGING TABLE If you have repeat position hole punching to do then you need one of our Gauging Table Kits. It comes with a 12" x 16" table that bolts onto the standard or oversize Pedestal Die Table. The kit also includes an adjustable fence bar for front to back and an adjustable fence bar for left to right positioning. Each fence bar has handles that clamp down to the table slots to guide your metal parts into the same position for making repeat parts. The safety guard was moved for the photo, but you must use the safety guards to help prevent accidents. |

|||

|

FENCE GUIDES: 12 inch long or 18 inch long A Fence

Bar can be used as a straight edge on your flat bar shear to guide

a perfect 90 degree cut. The flat bar shear table plate has a mounting

slot for it. |

|||

|

STRIPPER REDUCING PLATE: The purpose is to minimize distortion when punching thinner metals, especially when using smaller punches. It mounts to your stripper bar with 2 screws and has a spring loaded pin to align it. It can be swung away when its not used. |

|||

|

URETHANE STRIPPER: This special stripper works differently than the less expensive Stripper Reducing Plate because it maintains constant pressure while punching which will minimize distortion of delicate metal parts, thin metal parts and soft copper buss bars. |

|||

|

PROTRACTOR ANGLE GAUGE: Set any angle you want on this Protractor Angle Gauge when shearing flat steel or when punching slotted holes. The Protractor has notches every 15° and also at 22.5° but it is often used at 90°. It works by fitting into the slot on the shear table, punch gauging table or up against the punch table. Its also reversible so people who are left handed will find it just as easy to use. |

|||

|

WORK LIGHT: Is your show not well lit? Then consider this super bright LED work light that plugs into all Edwards Ironworkers made after 2014 with an M12 connector and has a 100,000 hour rating. Super durable lexan lens and magnetic base allow you to attach the light on any metal surface on the machine. Good lighting can help improve the quality of your work. |

|||

|

HYDRAULIC ACCESSORY CONNECTOR: This cool option allows you to easily plug in another machine to the hydraulic pump of your ironworker such as the pipe bender, 20 ton tabletop shop press, 40 ton, 60 ton, or 110 ton shop press, radius rolling machine or the horizontal press brake. See below. Since it is very difficult to install this later it must be ordered when you buy your machine. |

|||

|

EDWARDS PIPE & TUBE BENDER: This machine connects to

the Hydraulic Powerlink Connector on your new Edwards Ironworker. |

|||

|

EDWARDS 20 TON TABLE TOP PRESS: * Plug in accessory

to a new Edwards Ironworker machine that has the hydraulic accessory

connector option. |

|||

|

EDWARDS

LARGE HYDRAULIC SHOP PRESS: The 40 ton,

60 ton and 110 ton Shop Presses are available as a plug in accessory

to a new Edwards Ironworker machine that has the hydraulic accessory

connector.

|

|||

|

EDWARDS RADIUS ROLLING MACHINE: For curving flat bar, pipe,

tubing and angle iron. Plug it into your Edwards Ironworker with

the Hydraulic Accessory Connector. Dial in the variable speed hydraulic

drive for each bending jobs. Easily change the machine from vertical

for smaller parts to horizontal for long parts. The machine comes standard

with a set of flat rolls. |

|||

|

EDWARDS HORIZONTAL PRESS BRAKE: This machine comes with

standard V-die tooling for simple bends but you can put other different

tooling shapes on the vertical shafts of this machine to form, bend,

and straighten metal. This machine can quickly connect to your Edwards

Ironworker. Designed for maximum tooling flexibility, the 4 pin

locations are locked with a simple crank for inboard tool squaring.

Digital encoder reads positive stop for accurate repeatability within

0.01". |

|||

Click for the American Machine Tool Homepage

5862 Northwest Hwy

Chicago IL 60631 USA

Phone: 773-334-5000

Fax: 773-442-0314

Click to email us

Copyright © 2021

American Machine Tools Corp.

All rights reserved

Offers from American Machine Tools Corporation include include Terms and Conditions shown on our website.

Liability is strictly limited to those warranties of fitness for purpose and safety as provided by the manufacturer.

Products and Logos in this website are trademarks or registered trademarks of their respective companies or mark holders.